(1)Plugging Application

Gudao oil production plant of Shengli Oilfield applied shallow plugging in three wells, with a success rate of 100%.

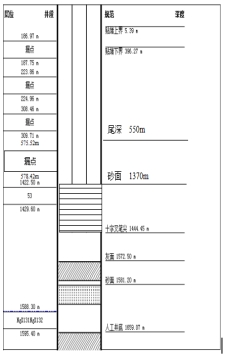

The shallow casing of well GO2-17-67 was blocked. The oxygen activation logging leak test of the well showed that the casing leaked at 575.52-578.42m, the cement return height was 113m, the finished depth of the surface casing was 339.73m, the test extrusion pressure at the leakage point was 0MPa, and there was no water return on the ground.

The shallow plugging construction was carried out on June 20, 2019. The well was connected to the 250 wellhead gate and prepared new inorganic gelling plugging agent 7m3 with density of 1.5-1.8g/cm3, positive displacement plugging agent 1.6m3, positive extrusion plugging agent slurry 5.4m3 and positive extrusion formation water 1.7m3. The pressure was controlled at 15MPa and maintained for five minutes to diffuse the pressure. And then reverse circulation well washing to wash out excess mortar. At last, the pipe string was lifted 150m, the pressure was kept at 13MPa and then the well was closed 72 hours to wait for condensation. After the pressure was tested at 10MPa, the shallow plugging was successful.

The casing of well GDGN201X4 was blocked. The leakage inspection of the well packer showed that the casing was leaking at 1419.83-1493.01m (plugging the leakage point section: 1431 - 14321442 - 14481454 - 145614591463 - 14731479 - 14811504m, a total of 21m). The cement return height was 0m, the leakage point squeeze test pressure was 2MPa, and the ground water return.

The shallow plugging construction was carried out on June 14, 2019. The well was connected to the 250 wellhead gate and prepared new inorganic gelling plugging agent 10m3 with density of 1.8g/cm3, positive displacement plugging agent 4.1m3, positive extrusion plugging agent slurry 5.9m3 and positive extrusion formation water 4.2m3. The pressure was controlled at 15MPa and maintained for five minutes to diffuse the pressure. And then reverse circulation well washing to wash out excess mortar. At last, the pipe string was lifted 150m, the pressure was kept at 11MPa and then the well was closed 48 hours to wait for condensation. After the pressure was tested at 10MPa, the shallow plugging was successful.

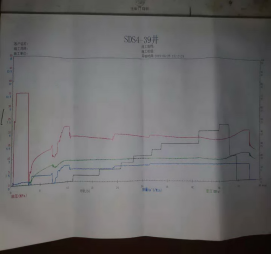

(2)Sand Control Application

Three water wells were applied in Lusheng Company of Shengli Oilfield. The water injection pressure before construction was 12 MPa, and the daily injection was 0m3. after construction, the water injection pressure was 7-10MPa and the daily injection was 80-100m3.