Phone:

Phone:

Phone:

Phone:

Shandong Ronman Petroleum Technology Co., Ltd.,

Address:

Contact:李先生

Phone:15969815807

1. Technical Introduction

Variable viscosity polymer HVFR-4, a synthetic polymer, can be used as sliding water drag reducer and linear gel thickener at the same time. It has the characteristics of high efficiency, low resistance and low residue. The molecular weight of the polymer is about 6-7 million, which is produced by emulsion polymerization. It is easy to break gel and break thoroughly.

2. Technical Characteristics

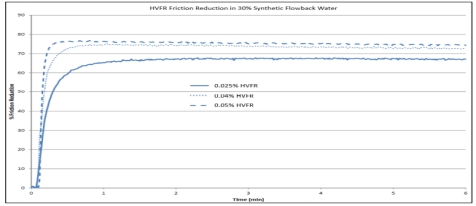

(1)Low viscosity slick water system: the recommended dosage is 0.05% - 0.1%, and the drag reduction rate is 74%.

Drag Reduction Efficiency of 0.05% HVFR-4 in 1% KCI Brine

(2)Variable viscosity polymer fracturing fluid system:

①Viscosity of fracturing fluid system

②Temperature and shear resistance of fracturing fluid

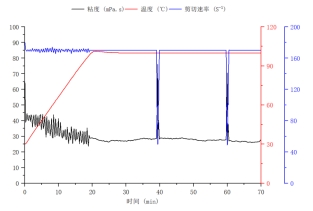

HVFR-4 temperature and shear resistance:

• Dosage: 0.5%

• Water quality: mineralization 1500mg/L

• Hydration time: 20s

• Test temperature: 100℃

• Shear rate: 100rpm/170s-1

• Test duration: 70min

• Final adhesion: 25MPa.s (good temperature resistance and shear resistance)

③Dynamic Sand Carrying Performance of Fracturing Fluid

p HVFR-4 carries 60% of the total sand production;

p Guar gum only carried 37% of the total sand;

p The sand carrying capacity of variable viscosity polymer fracturing fluid is better than that of linear gel.

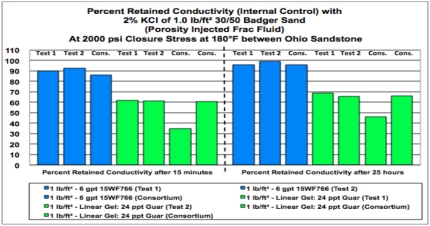

④Fracture Permeability Recovery Performance of Fracturing Fluid

The variable viscosity polymer contains less or almost zero insoluble matter, which is easy to be broken by oxidizing substances. There is no insoluble material that is easy to block the pore throat, and it has lower support crack penetration damage.

Comparison of permeability recovery between variable viscosity polymer (blue) and guar gum (green)

Copyright ©2021- Shandong Ronman Petroleum Technology Co., Ltd., All Rights Reserved.

网站地图