Phone:

Phone:

Phone:

Phone:

Shandong Ronman Petroleum Technology Co., Ltd.,

Address:

Contact:李先生

Phone:15969815807

Sand Control and Plugging Technology of Inorganic Composite Cementitious Material

1.Technical Introduction

The new inorganic composite material system is composed of SiO2, Al2O3, Fe2O3, CaO, SO3 and a small amount of periclase and perovskite through high-temperature sintering according to a certain proportion.This product is used as the main material and mixed with skeleton active materials with similar density and high strength. The above base materials are crushed and processed into ≤ 0.2mm, 0.2-0.5mm and 0.5 -1.2mm. Under the coordinated regulation of different admixtures, high-performance applications for different purposes can be realized.

(1) The particle size ≤ 0.2mm can be used for shallow plugging, plugging in drilling process, plugging abandoned layers, etc;

(2) 0.2 - 0.5mm can be used for the purposes of adjusting seepage profile and water plugging in large channels, as well as sand control of ultra-fine sandstone;

(3) The particle size of 0.5 - 1.2mm is mainly used for sand control in loose sandstone formation due to its high permeability and moderate strength.

2.Material Properties

A large number of indoor experiments show that the material system has the following main characteristics and properties:

(1)It can realize solidification under a wide temperature range, from negative temperature to high temperature of 120℃. Only the time is different.

(2)The compressive strength of the consolidated body formed after consolidation increase with the thinning of particle size. The compressive strength of particles less than 0.2 is up to 30MPa and above and the compressive strength of particles 0.5-1.2 is 8-15MPa and above.

(3)Under the adjustment of different admixtures, the different requirements of the consolidated body for permeability can be realized. If the particle size is less than 0.2, it is easy to achieve the purpose of low or zero permeability. If the particle size is 0.2-0.5, it is easy to adjust the permeability between tens of millidarcy and several darcy. And if the particle size is 0.5-1.2, it can adjust the permeability between several darcy and dozens of darcy.

(4)The material system has the characteristics of early strength and high strength, and can change with temperature and other conditions. The initial setting time of particles less than 0.2 can be adjusted from 2 hours to 8 hours, and the final setting time can be adjusted from 2 hours to 8 hours. The initial setting time of particles 0.2-0.5 can be adjusted from 50 minutes to 3 hours, and the final setting time can be adjusted from 3 hours to 10 hours. The initial setting time of particles 0.5-1.2 can be adjusted from 50 minutes to 12 hours.

(5)The consolidated body formed by the material has certain acid and alkali corrosion resistance. In strong acid and alkali environment, its strength decreases slightly but is not damaged, has certain high-temperature aging resistance.

(6)The void size distribution experiment of artificial core formed by large particle size material shows that the pore distribution is more uniform, which not only has high permeability, but also has good sand control effect.

(7)The bulk density of the material system is 1.15~1.25, which is convenient for filling and carrying.

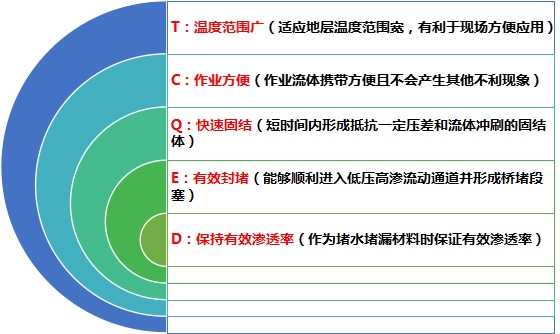

3. Technical Characteristics

4. Application

(1)The particle size of 0.5-1.2 can be used for artificial sidewall sand control of loose sandstone, which permeability can be controlled in several darcy to hundreds of darcy and the compressive strength can reach 8-15MPa and above.

(2)The liquid absorption or production profile of heterogeneous strata can be flexibly adjusted by using the particle size of 0.2-0.5.

(3)The particle size less than 0.2 can be used to plug the waste layer or shallow leakage, which compressive strength can reach 30MPa and above.

(4)pores or thermal production wells.

(5)Through the appropriate proportion of several particle sizes, the sand retaining function can be flexibly adjusted and the sand control effect can be improved.

Copyright ©2021- Shandong Ronman Petroleum Technology Co., Ltd., All Rights Reserved.

网站地图