Field Application

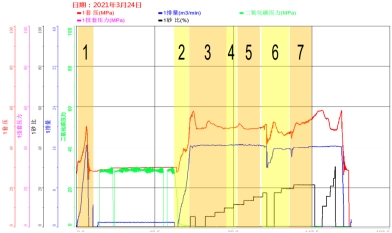

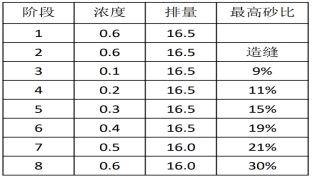

The first shale oil well was constructed in March, 2021. The well is designated to be fractured in seven section, which adopts the mode of high viscosity + low viscosity + high viscosity slick water injection and continuous sand addition.

First Section Fracturing Construction Data Curve

Data Sheet of First Stage Fracturing Operation

With the adaptation of the construction method of long slug +continuous sand addition, the maximum sand ratio in the medium viscosity slick water stage is 17% in the early stage and the sand ratio in the later stage. It shows that the sand carrying performance of fracturing fluid is good under the condition of high displacement. There are 18 perforations in the third cluster of sections 2, 3, 4. Although these perforations can significantly improve the liquid inlet efficiency of a single hole, the hole friction is high. So at the beginning of fracturing construction, it is extremely difficult to add sand when the displacement is 4-6m3/min and the construction pressure reaches about 60MPa. The use of low viscosity slick water + slug is an effective means, which can greatly reduce the fracture bending friction and create good conditions for subsequent main sand addition.

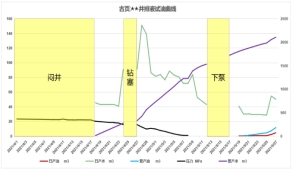

A total of 5878.12m3 fracturing fluid was injected into the well, which was shut in for 18 days after fracturing. At the beginning, the daily water production is 40- 45m3/d. after coiled tubing plugging, the initial water production increase to 90-150m3/d and remains basically stable. When the flowback rate is 20.29%, oil spray can be found and then pump was put down. After the pump is put into operation, the water production is 30-50m3/d, and the test oil production is 0.4-6m3/d. As of May 25, the cumulative liquid discharge was 38 days, and the flowback rate was 29.4%.

三、Micro-coil Control Technology

Field Case

①Reservoir overview--thin oil reservoir with ultra-low permeability, normal pressure, abnormal high temperature and fractures

¨ The reservoir is deeply buried, and the average depth in the middle of the oil layer is about 1936m.

¨ Recover efficiency is 22.0%

¨ The average porosity is 10.39%

¨ Average permeability is 1.93×10-3um2

¨ The viscosity of underground crude oil is 5.7 mPa.s

¨ The average reservoir temperature is 100 ℃

¨ The ground temperature gradient is 4.7℃/100m

¨ The PH value of formation water is about 8.0

¨ The gas oil ratio is 30.13m3/t

②Profile Control Pilot Test

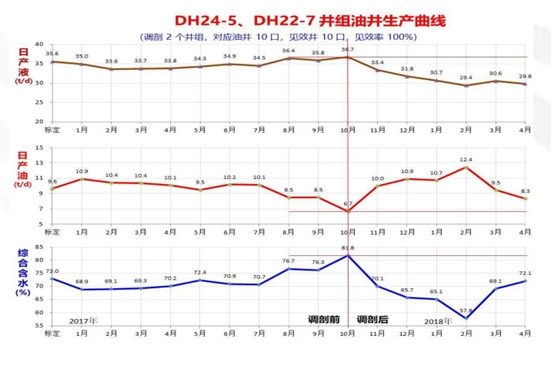

The two well groups correspond to 10 oil wells, with a daily liquid production of 36.7t/d, a daily oil production of 6.7t/d and a water cut of 81.8%. The wells in the well group are seriously flooded and have entered the stage of high water cut development. The development situation of the two well groups was poor before profile control. The water cut increased by 9.4% and the daily oil production decreased by 29.5% in five months.

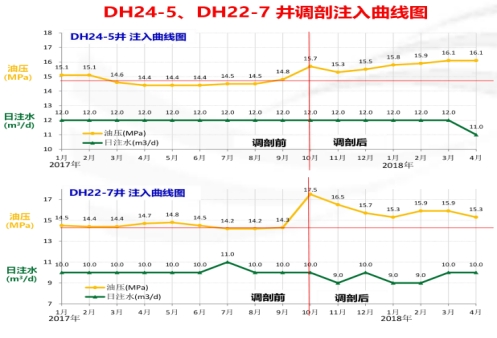

21t micro coil regulator was injected into two wells, the average injection increased from 14.5↑16MPa to 1.5MPa.

Application effect: there are 10 corresponding oil wells, all of which are effective, and the efficiency is 100%. Compared with that before profile control, the maximum water cut decreases by 24.0%, the maximum daily oil decreases by 5.7t/d, the maximum daily oil increases by 85.07%, and the input and output ratio is 1:2.

③Extended Experiment

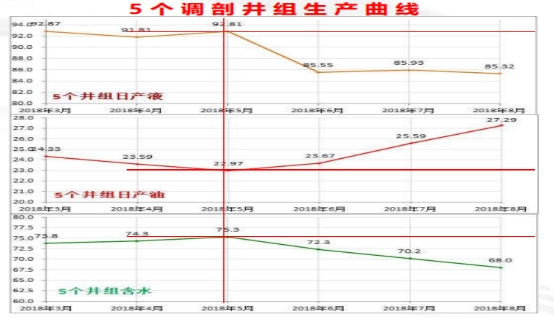

Based on the pilot test, it is decided to carry out the expanded test of five well groups. There are 30 oil wells corresponding to the five well groups, with 28 wells opened, 92.8t/d daily liquid production, 22.9t/d daily oil production and 75.3% water content. In four months, the water content of the well group increase by 4.8% and the daily oil production decrease by 15.0%.

Application effect: So far, four of the five well groups have achieved overall results, with an efficiency of 80%. The total daily liquid production decreased by 6.49 tons, and the daily oil production increased by 3.7 tons/day with an increase of 15.68%. and the comprehensive water cut decreased by 6.29%.